Essential Checklist for Sourcing the Best Pressure Release Valve: What Every Global Buyer Needs

In the realm of industrial safety and operational efficiency, the importance of selecting the right Pressure Release Valve (PRV) cannot be overstated. These critical components are designed to prevent dangerous overpressure conditions, protecting both machinery and personnel. According to a recent report by MarketsandMarkets, the global PRV market is projected to grow from USD 4.2 billion in 2021 to USD 5.6 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.8%. As industries increasingly recognize the value of reliable safety mechanisms, ensuring effective sourcing strategies for PRVs has become imperative for global buyers. This blog aims to provide an essential checklist for sourcing the best Pressure Release Valve, enabling procurement professionals to navigate considerations such as material compatibility, manufacturing standards, and regulatory compliance effectively.

Types of Pressure Release Valves: Understanding the Basics

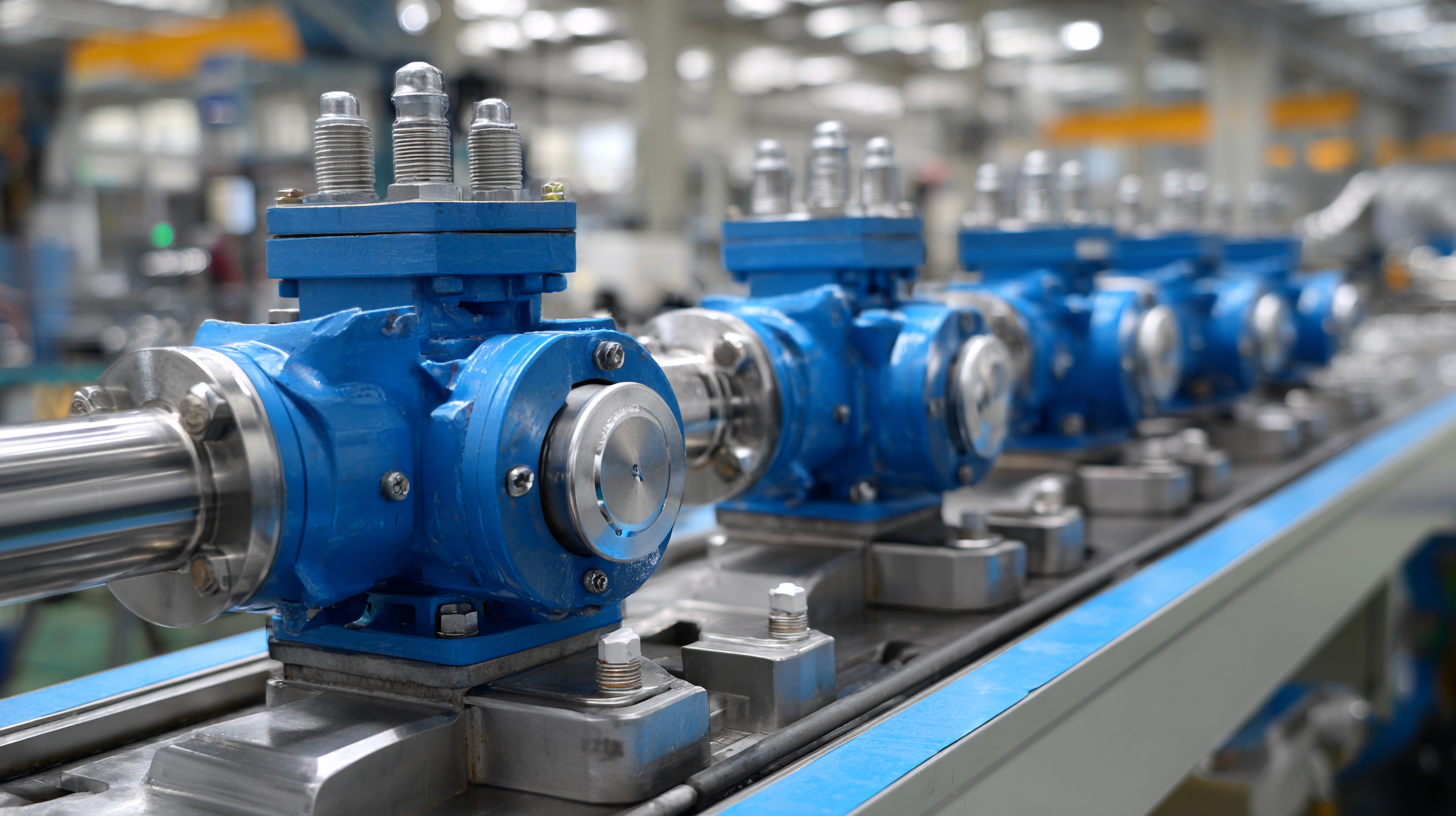

When sourcing pressure release valves, it’s crucial to understand the different types available to ensure you select the right one for your application. Pressure release valves primarily include spring-loaded, diaphragm, and pilot-operated types, each with unique operating mechanisms and applications. Spring-loaded valves are designed to release pressure when the force exceeds a preset threshold, making them ideal for various industrial uses. Diaphragm valves, on the other hand, offer more precise control and are often used in sensitive environments, such as laboratories.

Another type, the pilot-operated valve, utilizes a small pilot valve to control the larger main valve, allowing for more efficient operation in high-pressure systems. These valves are commonly employed in heating systems and industrial machinery where stable pressure control is essential. Understanding the distinctions between these types allows global buyers to make informed choices based on the operational demands and safety standards of their specific applications, ensuring reliability and efficiency in their systems.

Key Features to Examine When Choosing a Pressure Release Valve

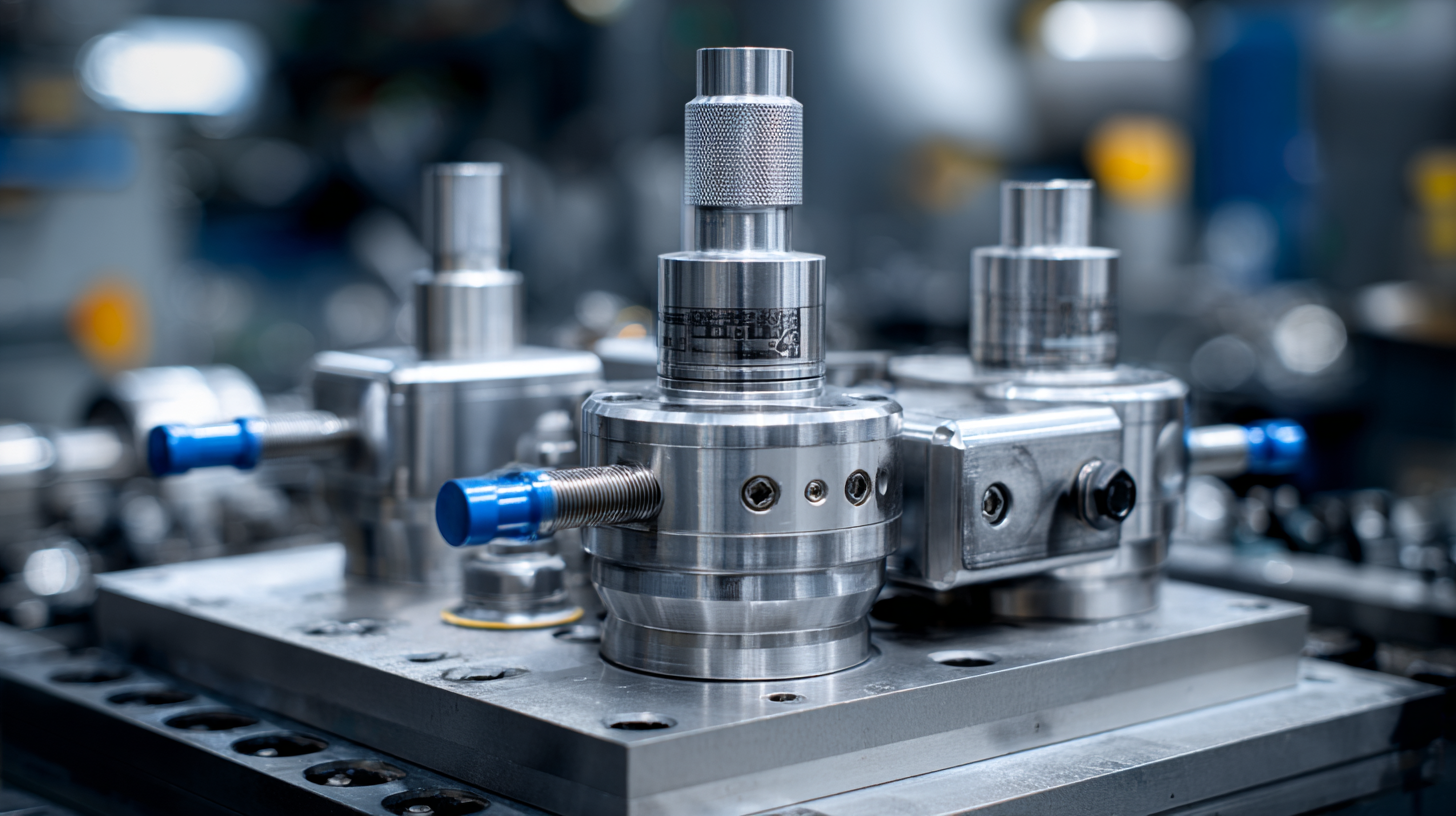

When sourcing the best pressure release valve, understanding the key features is crucial for ensuring safety and efficiency in your operations. First and foremost, material compatibility is essential. The valve must be constructed from materials that can withstand the specific pressures and temperatures of the application. Common materials include stainless steel and brass, which offer excellent corrosion resistance and durability. Additionally, consider the valve's pressure settings and the operational requirements of your system to avoid any failures or inefficiencies.

Another vital feature to examine is the valve's flow rate specification. A pressure release valve should be capable of handling the maximum flow volumes expected in your system without causing excessive pressure buildup. Look for valves with adjustable settings if your applications have varying requirements. Moreover, the design of the valve, including its mechanism of action—whether it’s spring-loaded or pilot-operated—can significantly impact responsiveness and operational reliability. Therefore, understanding these key features will enable global buyers to make informed decisions that best suit their specific needs.

Factors Influencing Pressure Release Valve Performance and Safety

When sourcing a pressure release valve, understanding the factors influencing their performance and safety is crucial. One of the primary elements is the valve's design and materials used. According to a report by MarketsandMarkets, the global pressure relief valve market is projected to reach $3.6 billion by 2025, underscoring the importance of selecting valves made from high-quality, durable materials that can withstand high pressures and temperatures.

Stainless steel and brass are commonly recommended for their corrosion resistance and strength, which are essential for maintaining safety in industrial applications.

Stainless steel and brass are commonly recommended for their corrosion resistance and strength, which are essential for maintaining safety in industrial applications.

Another significant factor is the valve's set pressure and flow characteristics. Research indicates that improper settings can lead to catastrophic failures, as highlighted in a safety study by the American Society of Mechanical Engineers (ASME) that shows improperly calibrated pressure relief valves are involved in an estimated 75% of pressure-related incidents. Buyers should ensure that the valve is tested according to established standards, such as ASME's PTC 25, which outlines performance evaluation criteria. By prioritizing these factors, global buyers can achieve not only cost-effective solutions but also enhance operational safety and reliability in their systems.

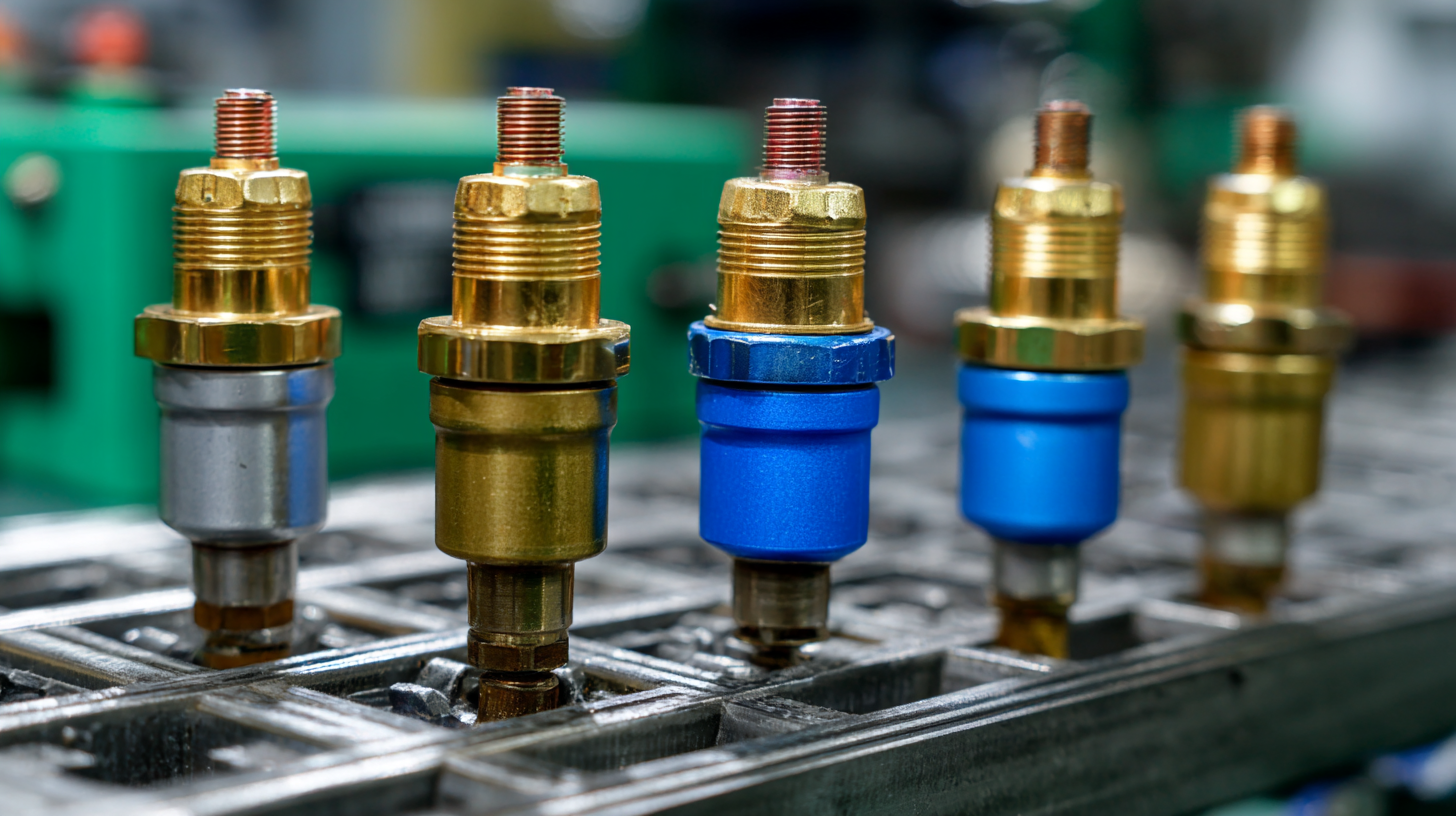

Common Materials Used in Pressure Release Valve Manufacturing

When sourcing a pressure release valve, understanding the common materials used in their manufacturing is crucial. Typically, pressure release valves are made from metals such as stainless steel, brass, and carbon steel due to their excellent strength and corrosion resistance. According to a report by MarketsandMarkets, the global pressure relief valve market is projected to reach USD 4.28 billion by 2025, driven largely by the increasing demand in the oil and gas, water treatment, and chemical processing industries. The use of materials like stainless steel, which can handle high temperatures and corrosive environments, is becoming more prevalent as industries look for reliable solutions that ensure safety and durability.

In addition to traditional metals, polymers like PTFE (Teflon) and PVC are also widely utilized, especially in applications where chemical resistance is essential. The Chemical Engineering magazine highlights that the choice of material can significantly impact a valve's performance and longevity. For instance, while brass is favored for its machinability and cost-effectiveness, PTFE offers advantages in highly corrosive environments where metal components may fail. Understanding the properties and applications of these materials is vital for global buyers looking to invest in pressure release valves that align with their operational needs and safety regulations.

Best Practices for Testing and Maintaining Pressure Release Valves

When it comes to safety equipment, pressure release valves play a crucial role in preventing overpressure situations. To ensure their reliability, regular testing and maintenance are essential. Firstly, a systematic approach to testing these valves should be put in place. This includes conducting pressure tests to confirm that the valve opens at the correct pressure. It is vital to document all test results meticulously, as this data can help identify any trends or recurring issues that may need further investigation.

Maintenance practices are equally important in prolonging the life of pressure release valves. A routine inspection schedule can help detect wear and tear, corrosion, or other damage that may compromise valve functionality. Cleaning the valves periodically ensures that debris does not hinder their operation, while replacing worn components can prevent failures. Additionally, keeping a record of maintenance activities allows for better planning and accountability, ensuring that all necessary operations are performed timely. By implementing these best practices, global buyers can maintain optimal performance and safety in their pressure systems.