How to Choose the Best Pilot Valve for Your Industrial Needs

When it comes to optimizing industrial processes, selecting the right components is crucial, and the Pilot Valve is no exception. This essential device plays a significant role in the control of fluid flow and pressure, ensuring that systems operate smoothly and efficiently. However, with a myriad of alternatives available in the market, making the right choice can be daunting. Various types of Pilot Valves come with different features, functionalities, and applications that cater to specific industrial needs. In this blog, we will explore the factors you should consider when choosing the best Pilot Valve for your requirements, examining the various alternatives available and helping you make an informed decision that will enhance your operations while maximizing cost-effectiveness and reliability. Whether you are working in manufacturing, oil and gas, or another industrial sector, understanding the nuances of Pilot Valves can provide you with the competitive edge you need.

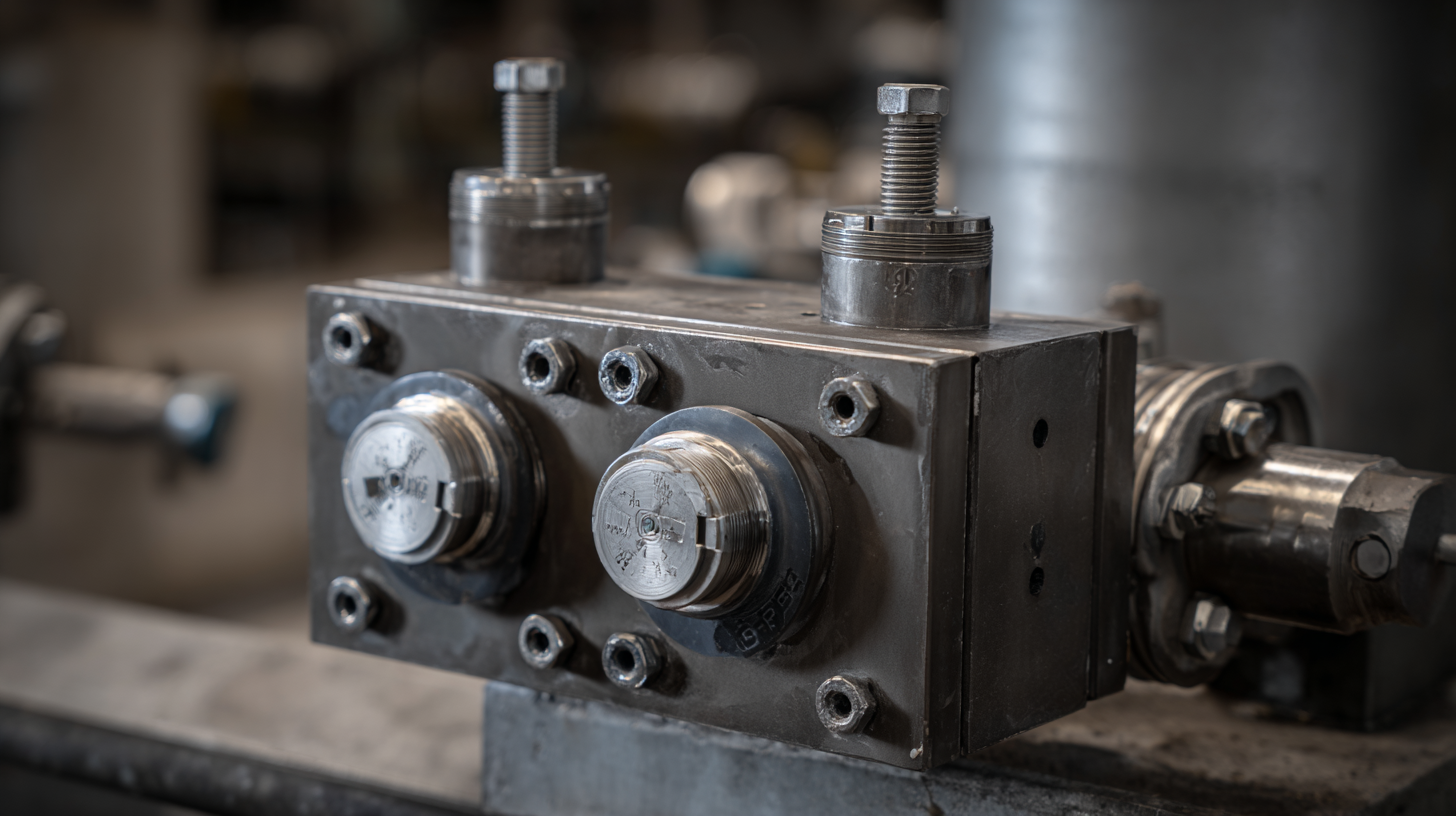

Understanding the Functionality of Pilot Valves in Industrial Applications

Pilot valves play a crucial role in industrial applications by controlling the flow and pressure of fluids in various systems. Their functionality directly impacts the efficiency and reliability of machinery in sectors such as manufacturing, oil and gas, and water treatment. According to a report by the International Society of Automation, improper valve selection can result in energy losses of up to 30%, which emphasizes the importance of choosing the right pilot valve tailored to specific industrial needs.

Cavitation is a common issue associated with pilot valves that can lead to reduced performance and potential damage. Research indicates that when fluid pressure drops below vapor pressure in a valve, small vapor-filled cavities form, leading to damage from subsequent shock waves. This phenomenon not only affects the longevity of the valves but can also compromise system stability. Ensuring the pilot valve is properly sized and materials are selected to withstand the operating conditions can significantly mitigate these issues, resulting in a much more efficient workflow. The right pilot valve can enhance operational safety and decrease maintenance costs, underlining their importance in industrial environments.

Key Factors to Consider When Selecting a Pilot Valve

When selecting the best pilot valve for your industrial needs, several key factors should be considered to ensure optimal performance. First, it's crucial to assess the operational requirements, including pressure levels, flow rates, and the specific application of the valve. For instance, pilot-operated solenoid valves are ideal for controlling high-pressure vessels, which may require a thorough understanding of their dynamic behavior to prevent potential failures.

Additionally, the design and materials of the valve play a significant role in its performance and longevity. With recent advancements in low-power solenoids, choosing valves that feature efficient energy consumption without compromising on speed or response time can enhance overall system efficacy. For industries such as coal mining or those involved with liquefied natural gas, understanding the relationship between power consumption and valve performance becomes crucial.

**Tips:**

- Always evaluate the environmental conditions and compatibility of the valve materials with the operating fluids to avoid premature wear and leaks.

- Utilize numerical simulations to predict the behavior of different valve types under varied conditions, which can provide invaluable insights for making informed decisions.

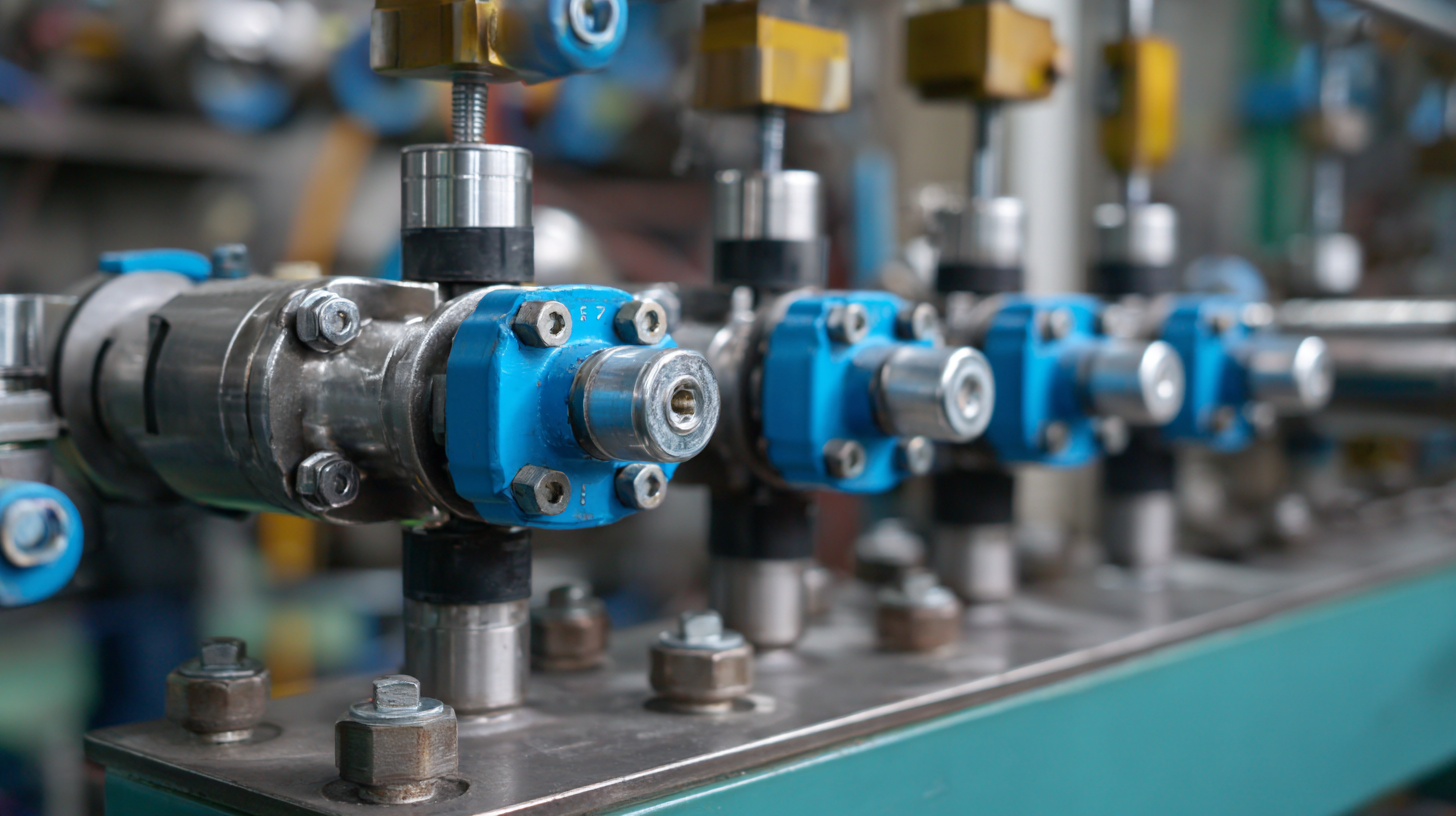

Types of Pilot Valves and Their Specific Use Cases

When selecting a pilot valve for industrial applications, understanding the various types available and their specific use cases is crucial. Pilot valves are essential components in controlling the flow of fluid or gas in numerous systems, and their effectiveness can significantly impact operational efficiency. According to a report from the International Society of Automation (ISA), the demand for automation technologies, which includes pilot valves, is projected to grow by 6.2% annually over the next five years. This growth underscores the importance of choosing the right type of pilot valve for your specific industrial process.

One common type of pilot valve is the solenoid valve, which is operated electrically and is often used in applications that require rapid switching. For instance, a study conducted by the Pneumatics Research Institute indicated that solenoid valves account for over 40% of the pilot valve market due to their reliability and speed. In contrast, mechanical pilot valves are preferred in environments where electrical components may pose safety risks. These valves can handle higher pressures and are often utilized in heavy machinery and oil and gas operations. As industries continue to evolve, integrating smart technologies with pilot valves is becoming increasingly common, enhancing the overall efficiency and safety of industrial systems.

Evaluating Compatibility with Existing Systems and Equipment

When selecting a pilot valve for your industrial application, it is crucial to evaluate its compatibility with your existing systems and equipment. Compatibility affects not only the immediate performance but also the long-term reliability and maintenance requirements of your system. Begin by assessing the specifications of your current setup, including pressure ratings, temperature ranges, and the type of fluid being controlled. Ensuring that the pilot valve meets or exceeds these parameters will help prevent operational issues down the line.

In addition to technical specifications, consider the physical connections between the pilot valve and your existing equipment. This includes checking the size, type of fittings, and valve orientation. Mismatches in these areas can lead to leaks or inefficiencies, negating any potential performance benefits. Furthermore, reviewing the manufacturer’s documentation can provide insights into the compatibility of the valve with various actuator technologies, which is essential for achieving optimal responsiveness and control in your operations. Adopting a thorough evaluation process will ensure that you select a pilot valve that seamlessly integrates into your industrial environment.

Best Practices for Maintenance and Troubleshooting Pilot Valves

When it comes to maintaining pilot valves, regular checks are essential for optimal performance. Ensure that the pilot valve is kept clean and free from debris, as accumulated dirt can impede its operation. A good practice is to perform routine inspections every few months, looking for signs of wear or leakage. If the valve is exposed to harsh environments, consider more frequent evaluations.

One important tip for troubleshooting pilot valves is to monitor the pressure levels regularly. Sudden drops in pressure can indicate blockages or malfunctioning components. Use a pressure gauge to keep track of these fluctuations, and don't hesitate to replace any faulty parts immediately. Additionally, ensure that all connections are secure to prevent leaks that can compromise your system.

Another useful practice is to maintain accurate records of all maintenance activities and any issues encountered. Documentation helps track the performance trends of the pilot valves, making it easier to identify recurring problems. This insight can lead to more effective troubleshooting, allowing for timely interventions before minor issues become major failures.