Unlocking Quality: Essential Tips for Sourcing the Best Pilot Valves Globally

In today's highly competitive manufacturing landscape, the significance of sourcing high-quality pilot valves cannot be overstated. According to a recent report by MarketsandMarkets, the global market for pilot valves is projected to reach $10.6 billion by 2025, growing at a CAGR of 4.7% from 2020. These critical components play a vital role in fluid control systems, impacting efficiency, safety, and overall operational performance.

Sourcing the best pilot valves globally requires a strategic approach that emphasizes quality and reliability, as subpar products can lead to costly downtime and decreased productivity. As industries increasingly move towards automation and advanced technologies, understanding the nuances of pilot valve selection and procurement becomes essential for maintaining competitive advantage and ensuring system integrity. In this blog, we will explore top strategies for sourcing pilot valves effectively, unlocking quality for your operations.

Identifying Key Features That Define Quality Pilot Valves

When sourcing pilot valves, identifying key features that define quality is paramount to ensuring optimal performance in your applications.

According to a report by MarketsandMarkets, the global pilot valve market is projected to grow at a CAGR of 5.4% from 2021 to 2026, driven by increasing automation across industries.

This underscores the importance of investing in high-quality pilot valves that can withstand varying operational pressures and flow rates without compromising reliability.

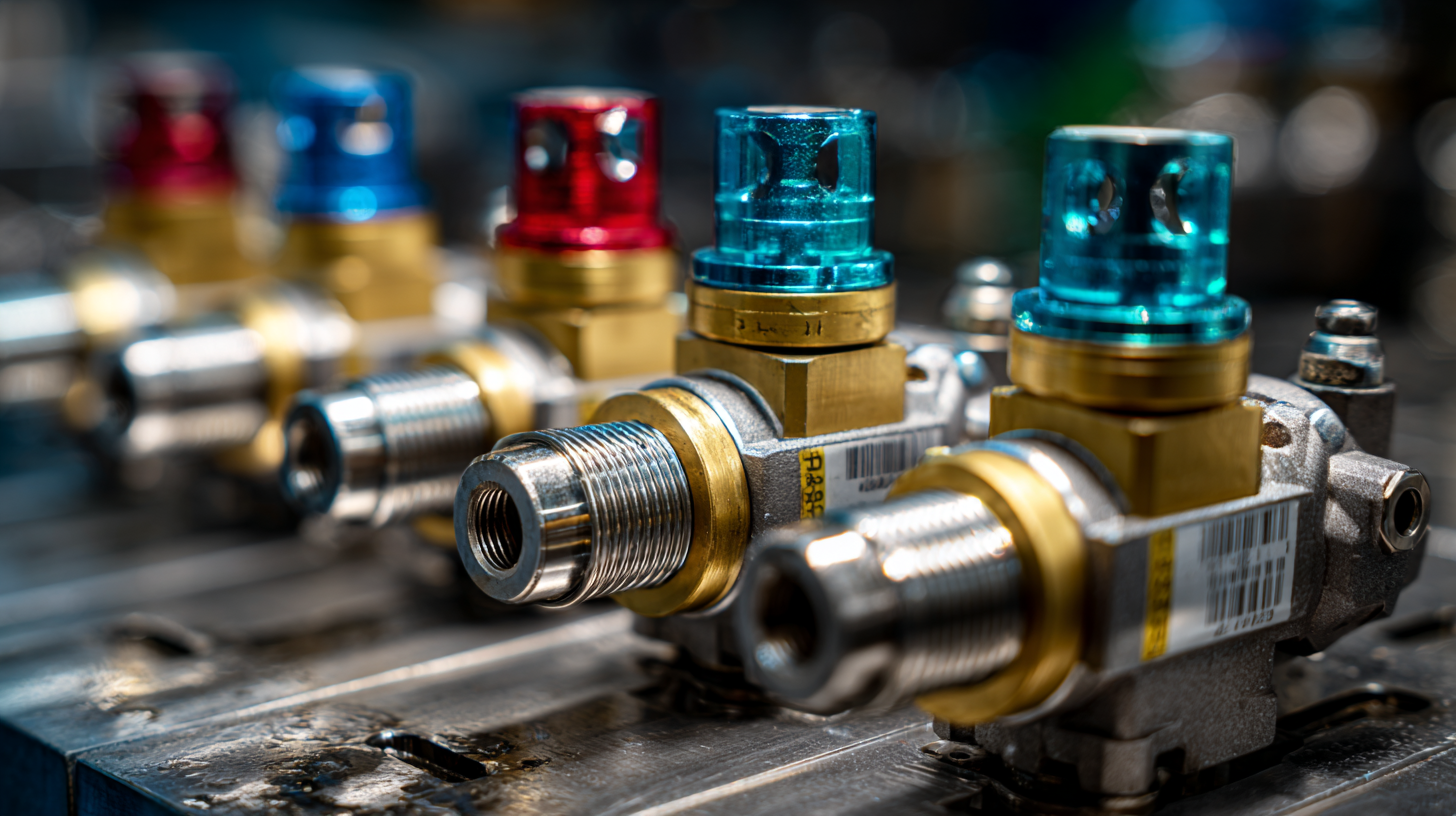

One critical feature to consider is the material of construction. Quality pilot valves are often made from corrosion-resistant materials such as stainless steel or specialized plastics, which not only enhance durability but also improve the valve's response time.

Furthermore, a study by the International Society of Automation highlights that pilot valves with high-cycle life ratings—often surpassing 1 million cycles—provide a better return on investment, as they reduce downtime and maintenance costs.

Performance specifications such as these are essential indicators of a pilot valve's quality and longevity in high-demand environments.

Understanding Different Types of Pilot Valves and Their Applications

Pilot valves play a crucial role in various industrial applications, acting as control devices that modulate the flow of fluids. Understanding the different types of pilot valves available is essential for optimizing performance and efficiency. Common types include needle valves, solenoid-operated valves, and pressure control valves, each designed for specific functions. Needle valves allow for precise flow adjustments and are often used in applications requiring delicate control, while solenoid-operated valves enable rapid switching and are ideal for automation processes.

Pilot valves play a crucial role in various industrial applications, acting as control devices that modulate the flow of fluids. Understanding the different types of pilot valves available is essential for optimizing performance and efficiency. Common types include needle valves, solenoid-operated valves, and pressure control valves, each designed for specific functions. Needle valves allow for precise flow adjustments and are often used in applications requiring delicate control, while solenoid-operated valves enable rapid switching and are ideal for automation processes.

In addition to these, pressure control valves serve to maintain system pressure, providing safety and stability. They are vital in hydraulic and pneumatic systems, ensuring that pressure levels do not exceed safe limits. Selecting the appropriate pilot valve depends not only on the characteristics of the fluid being controlled but also on the operational environment and intended application. By understanding these different types and their functions, professionals can make informed decisions when sourcing pilot valves, ultimately leading to enhanced system reliability and performance.

Evaluating Global Suppliers for Reliable Pilot Valves

When sourcing pilot valves globally, the reliability of suppliers is paramount. A well-informed evaluation process can make all the difference in ensuring the valves meet quality standards and operational efficiency. Start by researching potential suppliers, focusing on their reputation and track record in delivering consistent quality. Use platforms like industry forums, trade shows, and professional networks to gather insights and feedback from current and former customers. This grassroots intelligence can reveal a lot about a supplier’s reliability and product performance.

Next, consider the certifications and compliance standards upheld by these suppliers. Reliable pilot valve manufacturers typically adhere to international standards such as ISO, ANSI, or API, which can assure you of their commitment to quality and safety. Additionally, request samples for testing before making a large purchase. This practical evaluation allows you to analyze the valves’ performance under your specific operational conditions, helping you to make an informed decision. By prioritizing these evaluation criteria, you can ensure a successful partnership with global suppliers that deliver reliable and high-quality pilot valves.

Quality Control Measures in Pilot Valve Manufacturing

Quality control is a critical factor in the manufacturing of pilot valves, as it directly impacts performance and longevity. Ensuring a consistent standard requires implementing rigorous quality control measures at every stage of production. This begins with selecting the right materials; high-grade metals and components not only enhance the durability of pilot valves but also mitigate risks associated with failure in high-pressure applications. Manufacturers should prioritize sourcing from reliable suppliers who adhere to industry standards, ensuring that all materials undergo thorough testing before they enter the production line.

Furthermore, routine inspections and testing during the manufacturing process are essential to maintain quality assurance. Employing advanced technology such as automated testing equipment can streamline this process, enabling real-time monitoring of the assembly and welding stages. Techniques like non-destructive testing (NDT) and pressure testing ensure that any potential defects are identified and rectified early, reducing the chances of costly recalls or failures. By emphasizing these quality control measures, manufacturers can produce pilot valves that meet the stringent demands of various applications, ultimately unlocking exceptional performance and reliability in the global market.

Cost vs. Quality: Making Informed Sourcing Decisions for Pilot Valves

When sourcing pilot valves, one of the most critical considerations is the balance between cost and quality. While it might be tempting to opt for the lowest price, this can often lead to compromised quality and performance issues down the line. Understanding the long-term implications of sourcing decisions is vital; investing in high-quality pilot valves may come with a higher initial cost, but it often results in better reliability, reduced maintenance, and overall cost savings in the operation of a system.

To make informed sourcing decisions, it's essential to analyze supplier credentials, material specifications, and compliance with industry standards. Engaging with manufacturers who prioritize quality assurance can provide insights into their production processes and testing methods. Additionally, building a relationship with suppliers that offer transparency in pricing and product quality can enhance trust and lead to better purchase decisions in the long run. Therefore, by emphasizing quality over merely seeking a low upfront cost, companies can secure pilot valves that not only meet their operational needs but also contribute to overall efficiency and safety.