Top Strategies for Selecting the Best Control Valve for Your Industrial Needs

In the realm of industrial automation, the selection of the right control valve is paramount for optimizing process efficiency and ensuring reliable operations. Recent studies indicate that control valves can account for up to 30% of a facility’s total energy consumption, underscoring the critical role they play in various applications, from oil and gas to water treatment. Moreover, the global control valve market is projected to reach $10.2 billion by 2025, highlighting the increasing demand for sophisticated valve technology that meets specific industrial needs. As industries evolve with advanced automation technologies, understanding the nuances of different control valve types and their respective advantages is essential for engineers and procurement specialists. This blog aims to provide a comprehensive comparison of top strategies for selecting the most suitable control valve, ensuring that businesses can enhance operational efficiency while effectively managing costs.

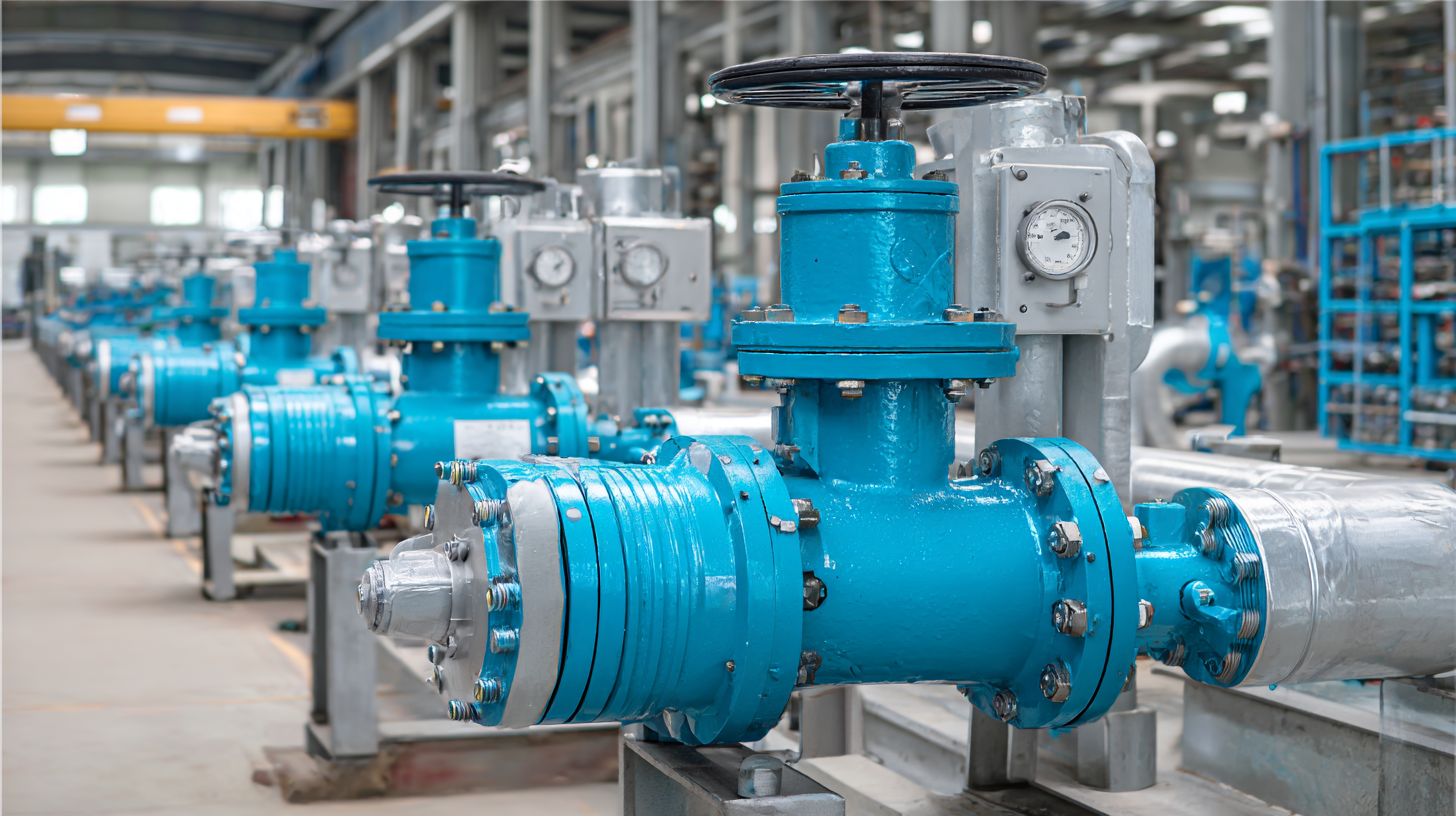

Identifying Key Industrial Applications for Control Valves

Control valves play a crucial role in managing the flow of fluids within various industrial applications. From chemical processing to water treatment, the choice of a control valve can significantly impact system efficiency and operational safety. According to a recent report by the Valves & Actuators Market Outlook, the global control valve market is projected to reach $10 billion by 2025, driven by increased demand across sectors such as oil and gas, power generation, and food and beverage. Each of these industries requires specific control valve features to address their unique operational challenges.

In the oil and gas sector, for instance, the harsh environmental conditions necessitate the use of rugged and reliable control valves that can withstand significant pressure fluctuations. A study by the American Petroleum Institute highlights that up to 30% of operational issues in oil and gas extraction can be attributed to valve failures. Conversely, in the food and beverage industry, compliance with stringent hygiene standards requires valves made of corrosion-resistant materials with precise flow control capabilities. According to a report from Research and Markets, the food and beverage segment is expected to expand at a CAGR of 4.5% from 2023 to 2028, underscoring the need for advanced control valve solutions. Understanding these industrial applications is vital for selecting the right control valve to meet specific operational needs.

Top Strategies for Selecting the Best Control Valve for Your Industrial Needs - Identifying Key Industrial Applications for Control Valves

| Application Area | Control Valve Type | Key Features | Ideal for |

|---|---|---|---|

| Oil & Gas | Ball Valve | High flow capacity, low pressure drop | Pipeline transportation |

| Water Treatment | Globe Valve | Precise flow control | Chemical dosing |

| Power Generation | Pressure Relief Valve | Safety regulation under extreme conditions | Steam and gas systems |

| Food & Beverage | Butterfly Valve | Quick opening and closing, hygienic design | Process control |

| Chemical Processing | Diaphragm Valve | Leak-proof seal, low maintenance | Corrosive fluid handling |

Understanding the Different Types of Control Valves Available

When selecting the best control valve for industrial applications, it's crucial to understand the various types available. Control valves can be categorized mainly into globe valves, ball valves, butterfly valves, and gate valves, each offering unique advantages suited to different operational needs. For instance, globe valves are renowned for their ability to regulate flow effectively, while ball valves are preferred for on-off control due to their quick operation.

Tip: Consider the specific requirements of your application, such as pressure, temperature, and flow rate. This will help narrow down the options to those that can withstand the operating conditions efficiently.

Tip: Regular maintenance and monitoring of control valves can prevent issues like stiction and prolong their operational lifespan. Evaluate innovative technologies that address current challenges in valve performance to ensure optimal functionality.

Evaluating Performance Criteria for Optimal Valve Selection

When selecting the ideal control valve for industrial applications, evaluating performance criteria is crucial. According to a recent report by Global Market Insights, the control valves market is projected to reach over $10 billion by 2026, highlighting their importance in industrial processes. Key performance criteria include flow characteristic, pressure drop, Cv value (flow coefficient), and the valve's materials compatibility with the media being controlled.

Flow characteristic defines how the valve behaves in response to the control signal. It is essential to choose a valve with the right flow characteristic—linear, equal percentage, or quick opening—matching the specific process requirements. Additionally, pressure drop is significant because it affects system efficiency and energy consumption. A control valve with a proper Cv value ensures that sufficient flow is achieved without causing excessive energy losses. Furthermore, materials compatibility refers to the valve's ability to withstand the corrosive or abrasive nature of the fluids involved, which can influence both the lifespan of the valve and system reliability. Conducting a thorough evaluation of these performance criteria ensures optimal valve selection tailored to specific industrial needs.

Top Strategies for Selecting the Best Control Valve for Your Industrial Needs

Assessing Manufacturer Reliability and Product Certifications

When selecting control valves for industrial applications, assessing manufacturer reliability is crucial. A reputable manufacturer should have a proven track record of quality and performance. Researching their history, customer reviews, and industry reputation can provide insights into their reliability. Look for manufacturers that have been in the industry for several years and have successfully delivered products across various applications. This experience often translates to better design, durability, and customer service, which are essential for seamless operations.

In addition to reliability, product certifications play a significant role in selection. Certifications from recognized standards organizations, such as ISO or ASTM, indicate that the control valves meet specific quality and safety criteria. These certifications assure customers of the product’s performance and compliance with industry regulations. When evaluating potential options, inquire about the certifications held by the manufacturer and ensure the control valves align with your operational requirements. This attention to certification details not only enhances operational safety but also mitigates long-term risks, ensuring you invest in a product that supports your industrial needs effectively.

Integrating Control Valves with Automation Systems for Efficiency

When integrating control valves with automation systems, efficiency becomes paramount in ensuring that industrial processes run smoothly and effectively. A well-selected control valve not only regulates flow and pressure but also contributes to the overall responsiveness of the automation system. An essential factor to consider is the compatibility of the control valve with existing automation protocols. Many modern systems utilize standardized communication protocols, such as HART or Fieldbus, which facilitate seamless integration and data exchange between devices.

Furthermore, advanced control valves equipped with smart technologies enhance automation capabilities. These valves can provide real-time data on performance metrics, enabling predictive maintenance and reducing the risk of unexpected failures. The ability to remotely monitor and adjust valve settings helps streamline operations, ultimately leading to increased productivity and reduced operational costs. By prioritizing the synergy between control valves and automation systems, industries can achieve a higher level of operational excellence and adaptability in an ever-evolving market.